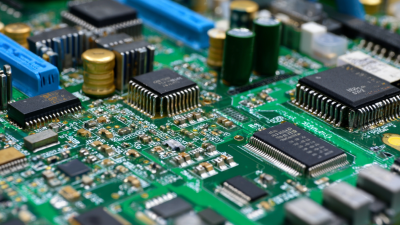

As we approach 2025, the landscape of circuit board manufacturing is evolving rapidly, driven by technological advancements and market demands. According to a report by ResearchAndMarkets, the global printed circuit board (PCB) market size is expected to reach USD 83.7 billion by 2025, growing at a CAGR of 3.4% from 2020. This growth is largely attributed to the increasing complexity of electronic devices and the rising demand for high-performance components across various sectors, including automotive, consumer electronics, and telecommunications.

In this dynamic environment, several key trends are poised to shape the future of circuit board manufacturing. Emerging technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), are not only enhancing production efficiency but also enabling the development of more sophisticated circuit designs. Additionally, sustainability initiatives within the industry are driving the adoption of eco-friendly materials and processes, aligning with the global push for greener manufacturing practices. As we delve into the top five trends influencing circuit board manufacturing in 2025, we will explore how these shifts are transforming the production landscape and paving the way for innovation.

The landscape of circuit board manufacturing is on the brink of a major transformation, driven by emerging technologies poised to revolutionize the industry by 2025. According to a recent report by the IPC (Institute of Printed Circuits), the global market for circuit boards is projected to reach $82 billion by 2025, with a CAGR of 4.8% from 2020 to 2025. Innovations such as automated manufacturing processes and IoT integration are central to this growth. Automation not only enhances efficiency but also significantly reduces the rate of human error, ensuring higher quality products.

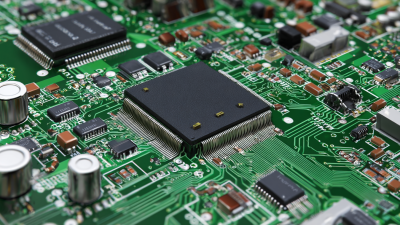

Furthermore, the integration of advanced materials like flexible substrates and high-density interconnects (HDI) is reshaping product capabilities. A study by Frost & Sullivan highlights that adopting HDI technology can improve performance metrics by up to 40%. Additionally, the rise of 5G technologies is creating new demands for faster and more compact circuit designs, leading to increased investments in R&D. As companies navigate these evolving trends, the focus on sustainable manufacturing practices will also intensify, with industry leaders seeking to minimize environmental impact while maximizing productivity.

| Trend | Description | Impact on Manufacturing | Emerging Technologies |

|---|---|---|---|

| Miniaturization | Devices are becoming smaller, demanding highly compact circuit boards. | Increased need for advanced designs and precision engineering. | Microfabrication techniques, 3D printing. |

| Sustainable Manufacturing | Focus on eco-friendly materials and waste reduction processes. | Shift towards greener practices and materials can reduce costs in the long term. | Biodegradable substrates, water-based soldering. |

| Smart Manufacturing | Integration of IoT devices for real-time monitoring and efficiency. | Increased operational efficiency and reduced downtime. | AI-driven analytics, machine learning algorithms. |

| Flexible Electronics | Development of bendable and stretchable circuit boards. | Opens new markets in wearables and compact devices. | Conductive inks, flexible substrates. |

| Advanced Materials | Innovations in materials to enhance performance under various conditions. | Enhancements in thermal management and electrical performance. | Graphene, high-frequency substrates. |

As the circuit board manufacturing industry evolves, sustainability practices are becoming pivotal in enhancing efficiency across PCB production processes. According to a report from IPC, nearly 60% of PCB manufacturers have incorporated sustainable practices within their operations, significantly reducing waste and energy consumption. By embracing eco-friendly materials and processes, companies not only meet regulatory standards but also appeal to environmentally conscious consumers, thereby gaining a competitive edge in the market.

Recent data from the electronics industry highlights that the adoption of sustainable manufacturing techniques can lead to a reduction in production costs by up to 30%. This efficiency gain is primarily driven by innovative recycling practices, where manufacturers reclaim valuable materials from defective boards, thus reducing the need for new materials and minimizing environmental impact. Furthermore, investment in energy-efficient machinery and renewable energy sources is becoming increasingly common. A survey conducted by Deloitte revealed that 45% of manufacturers are planning to shift towards renewable energy solutions, reflecting a strong commitment to sustainable growth in the circuit board sector.

The integration of IoT and AI into circuit board design and manufacturing is revolutionizing the industry, driving innovations that enhance efficiency and functionality. As reported, the Electronic Design Automation Software market is projected to reach USD 32.15 billion by 2034, reflecting a significant demand for advanced design tools that incorporate AI technologies. Companies are increasingly leveraging physics-driven artificial intelligence to automate PCB design processes, significantly reducing the time and labor traditionally associated with manual design methods.

In Thailand, a strategic investment in AI-driven manufacturing facilities is positioning the country as a key player in PCB production. This shift is supported by ongoing collaborations between educational institutions and industry leaders to cultivate global semiconductor talent. The implications of these advancements were further discussed at the AI Meets Electronics Manufacturing Symposium, emphasizing the transformative role of AI in creating smarter, more responsive manufacturing environments. The emergence of these trends highlights how technology is not merely a tool but a catalyst for innovation in PCB manufacturing and design.

In the rapidly evolving landscape of circuit board manufacturing, supply chain optimization stands as a crucial pillar for advanced production methods. Manufacturers are increasingly focusing on integrating technology and data analytics to streamline their supply chains. By leveraging real-time monitoring and predictive analytics, companies can enhance visibility across the supply chain, reducing lead times and minimizing waste. This proactive approach allows manufacturers to anticipate demand fluctuations, ensuring they maintain adequate stock levels of essential components.

Furthermore, collaboration across the supply chain is becoming paramount. Manufacturers are establishing closer partnerships with suppliers to foster transparency and responsiveness. By sharing information regarding inventory levels and production schedules, companies can synchronize their efforts more effectively. This collaborative strategy not only enhances efficiency but also empowers faster responses to market changes. As the industry continues to embrace automation and smart technologies, the emphasis on supply chain optimization will significantly shape the future of circuit board production, driving innovations that meet the demands of an increasingly complex market.

The evolving landscape of PCB (printed circuit board) manufacturing is not just about technological advancements; it significantly impacts workforce development and the skills required for the future. According to a recent report by IPC, the global PCB market is expected to reach $100 billion by 2025, driven largely by innovations in smart technology and IoT devices. As production scales up, the demand for skilled professionals who can navigate these complex technologies will only intensify. This increasing reliance on advanced manufacturing processes necessitates a workforce proficient in automation, design software, and even artificial intelligence, which are becoming integral to PCB production.

Moreover, the changing dynamics of the industry highlight an urgent need for education and training programs tailored to these emerging competencies. A study from the Semiconductor Industry Association indicates that nearly 70% of companies in the semiconductor and PCB sectors are struggling to find workers with the right skill sets. This gap underscores the importance of collaboration between academia and the manufacturing sector to create curriculum frameworks that focus on practical experience and up-to-date technical knowledge. By aligning educational initiatives with industry needs, we can cultivate a future-ready workforce capable of meeting the demands of an increasingly complex PCB manufacturing environment.