Choosing the right PCB board is crucial for the success of any electronics project, as it serves as the backbone of your design, connecting various components and enabling functionality. In a world where digital technology is evolving rapidly, understanding the different types of PCB boards available is essential for engineers and hobbyists alike. Factors such as substrate material, layer count, and manufacturing capabilities can significantly impact the performance and reliability of your final product.

This article will guide you through the best practices for selecting the ideal PCB board tailored to your project needs, ensuring that you can make informed decisions based on both your technical requirements and budget constraints. Navigating the complexities of PCB board selection has never been more critical for achieving efficient and effective electronic designs.

When choosing the right PCB board for your project, it is crucial to first understand your project requirements and objectives. Begin by assessing the specific functions your circuit needs to perform. Identify the key parameters such as power requirements, signal integrity, and the operating environment. For example, wireless devices may need a PCB that supports RF signals, while power electronics might require robust thermal management features. Understanding these factors will help in selecting a PCB that can efficiently handle the demands of your application.

Additionally, consider scalability and future modifications. If your project is likely to evolve, opting for a versatile PCB design can save time and resources in the long run. Evaluate whether your project may require a multilayer PCB for complex connections, or if a simple single-layer board will suffice. By aligning the PCB specifications with your project's current and potential future needs, you enhance both performance and cost-effectiveness, ensuring that your project meets its objectives without unnecessary complications.

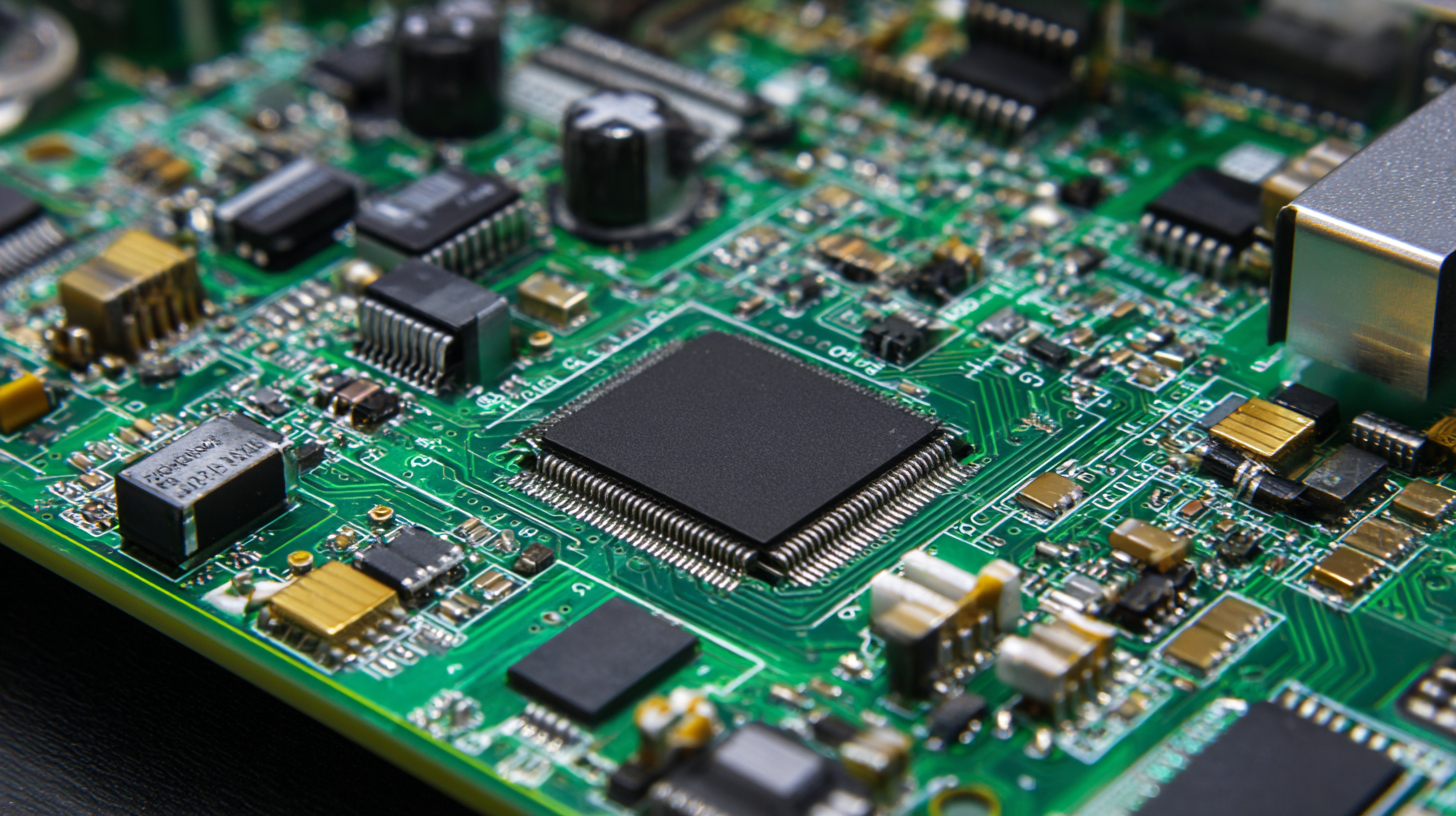

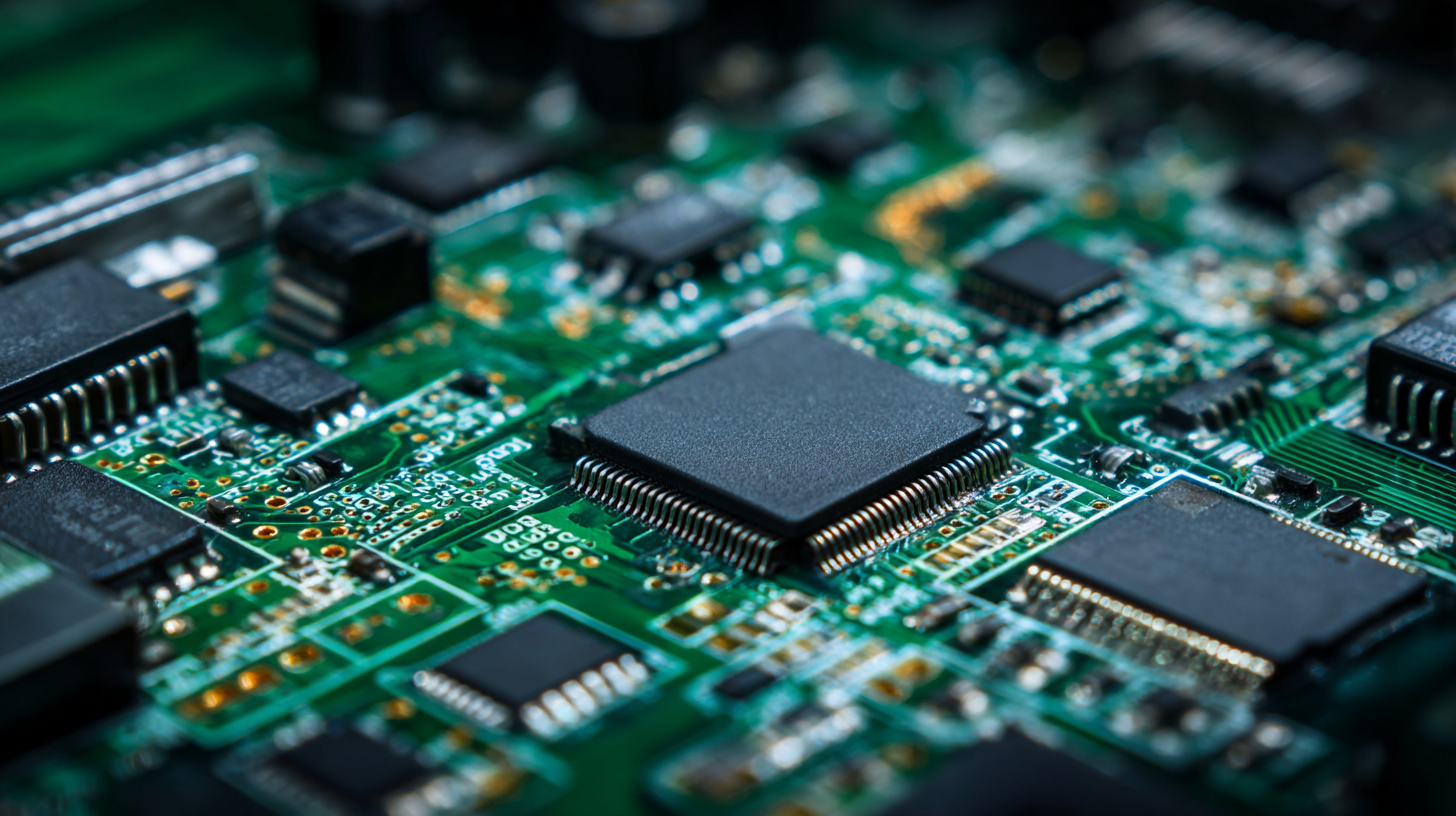

When selecting the right PCB board for a project, understanding the various types of PCB materials and their applications is crucial. The PCB market is diverse, encompassing rigid boards, flexible boards, and HDI boards, each designed to meet specific industry needs. Rigid PCBs, often categorized as single-sided and double-sided boards, are widely used in consumer electronics, telecommunications, and automotive applications. In contrast, flexible PCBs offer adaptability for compact designs, making them suitable for wearable technology and other innovative electronic devices.

The global automotive PCB market is projected to experience significant growth, with forecasts indicating an increase from $9.15 billion in 2023 to $15.1 billion by 2032, driven by the rising demand for advanced driver-assistance systems and electric vehicles. Additionally, the consumer electronics segment continues to expand, supported by innovations in smartphone and smart home technology. As industries evolve, PCB manufacturers are also adapting to trends such as surface mount technology and advanced material composites, enhancing performance while meeting the needs of various applications.

When selecting a PCB board for your project, understanding key specifications is crucial to ensure optimal performance and functionality. Firstly, consider the substrate material, which affects thermal properties and overall durability. For high-frequency applications, materials like FR-4 or Rogers are ideal, while for more standard projects, basic FR-4 may suffice.

Secondly, evaluate the number of layers your PCB requires. A simple design may only need a single layer, whereas complex circuits might necessitate multilayer boards to accommodate increased circuitry and reduced size. This can also influence manufacturing costs, so it's essential to strike a balance between complexity and budget.

Tip: Always check the manufacturer’s capabilities regarding the specs you have in mind. This can help prevent design changes later in the process.

In addition, do not overlook the importance of trace width and spacing, which are vital for current carrying capacity and signal integrity. Thicker traces are beneficial for high-current paths, while tight spacing can help reduce the board's overall footprint without sacrificing performance.

Tip: Utilize a PCB design software tool that simulates trace widths and spacing to identify potential issues early in the design phase.

When selecting the right PCB board for your project needs, it is crucial to evaluate manufacturing capabilities and costs effectively. According to a report from IPC, the global PCB market value reached approximately $60 billion in 2022 and is expected to grow by 3-5% annually. This growth indicates a diversified range of manufacturing capabilities available from various suppliers, which can be tailored to meet specific project requirements. Consideration of factors such as material types, layer counts, and special features (like impedance control or blind/buried vias) is essential.

Manufacturing costs are significantly influenced by the complexity and volume of the PCB production. A study from the Electronic Industries Alliance (EIA) highlights that prototyping costs can vary widely—from as low as $500 for simple boards to over $5,000 for advanced multilayer boards. Additionally, bulk production often allows for economies of scale, with larger orders reducing the per-unit cost significantly. Understanding these cost dynamics, along with the capabilities of potential manufacturers, is vital for optimizing your budget and ensuring quality in your final product.

| PCB Type | Material | Layer Count | Cost per Unit | Lead Time (Days) | Min Hole Diameter (mm) | Max PCB Size (mm) |

|---|---|---|---|---|---|---|

| Standard FR-4 | FR-4 Epoxy | 2 | $5.00 | 10 | 0.3 | 300x200 |

| High Frequency | PTFE | 4 | $15.00 | 15 | 0.2 | 250x150 |

| Flexible PCB | Polyimide | 1-2 | $20.00 | 20 | 0.2 | 200x100 |

| High-Power PCB | Copper Core | 2-6 | $25.00 | 25 | 0.35 | 300x300 |

When selecting the right PCB board for your project, one of the most critical aspects to consider is the balance between performance and budget constraints. Each project has unique requirements, such as the need for high-frequency signals or increased durability, which can often drive costs up. It's essential to identify the specific performance features that are vital for your application while also keeping an eye on the overall budget.

In today’s market, there are numerous options available, each with varying specifications and price points. To make the best choice, it is crucial to evaluate the trade-offs involved. For instance, opting for a higher-quality material might enhance performance but can significantly increase costs. On the other hand, budget-friendly options may compromise on durability or signal integrity. Therefore, conducting thorough research and understanding the specific needs of your project will enable you to select a PCB that meets both performance criteria and financial limits, ensuring a successful outcome.