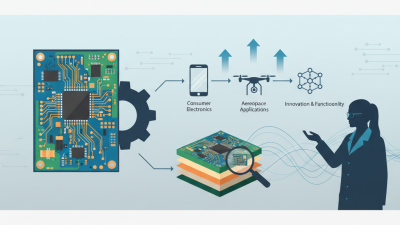

Choosing the right PCB fabrication and assembly service is crucial for any electronics project. The industry has grown significantly, with a reported annual growth rate of 6.5% from 2021 to 2026. This underscores the increasing demand for quality PCB services. However, many companies still overlook essential factors when selecting a provider.

Dr. Emily Chen, a leading expert in PCB technology, emphasizes, "Choosing the right fabrication service can make or break your project." Her insights resonate strongly with small businesses that may lack the resources for extensive testing. Finding a balance between cost and quality is often challenging.

It's important to assess providers based on their technology, turnaround time, and expertise. Relying solely on low prices may lead to subpar results. The right partner can significantly impact your product's performance and reliability. Being mindful of these aspects can prevent costly mistakes down the line.

When selecting a PCB fabrication and assembly service, understanding key terminology is essential. Terms like "bare board," "assembly level," and "via" are fundamental. A bare board is a printed circuit board without any components installed. Knowing this helps in identifying what stage you require. Assembly level refers to how completed the PCB is, which can impact costs and timelines.

Consider the different types of vias used in PCB designs. There are through-hole and blind vias, each serving distinct functions. Through-hole vias connect layers from one side of the board to another, while blind vias link only to certain layers. Clarity on these terms will help you communicate better with providers.

Don’t overlook the importance of materials. FR-4 is a standard, yet there are alternatives like polyimide. Each material affects cost, durability, and heat resistance. It can be daunting to navigate these options, and mistakes can be costly. Carefully research your needs to avoid confusion in the process. Reflecting on past experiences can shape your decisions today.

This bar chart illustrates a comparative analysis of the cost per unit for different PCB fabrication and assembly services. Understanding these costs can help in choosing the right service that fits your budget while ensuring quality and efficiency.

When selecting a PCB manufacturer, assessing certifications and industry standards is crucial. A credible manufacturer typically holds ISO 9001 certification. This reflects a commitment to quality management systems. According to recent industry data, about 70% of customers prioritize ISO certifications when choosing suppliers. This underscores the importance of these standards.

Another significant certification is IPC-A-600. This standard addresses the acceptability of printed boards. Research shows that boards meeting IPC standards demonstrate a 30% reduction in defects. Manufacturers with IPC certifications are often more reliable. They ensure that products meet rigorous industry benchmarks.

It’s also important to consider the specific needs of your project. Sometimes manufacturers can have the right certifications but lack experience in your industry. This gap may lead to misunderstanding technical specifications. Regularly reviewing certifications can also be beneficial. Manufacturers may allow their certifications to lapse, which might not align with your quality requirements. Choosing a partner who actively maintains their credentials can mitigate risks.

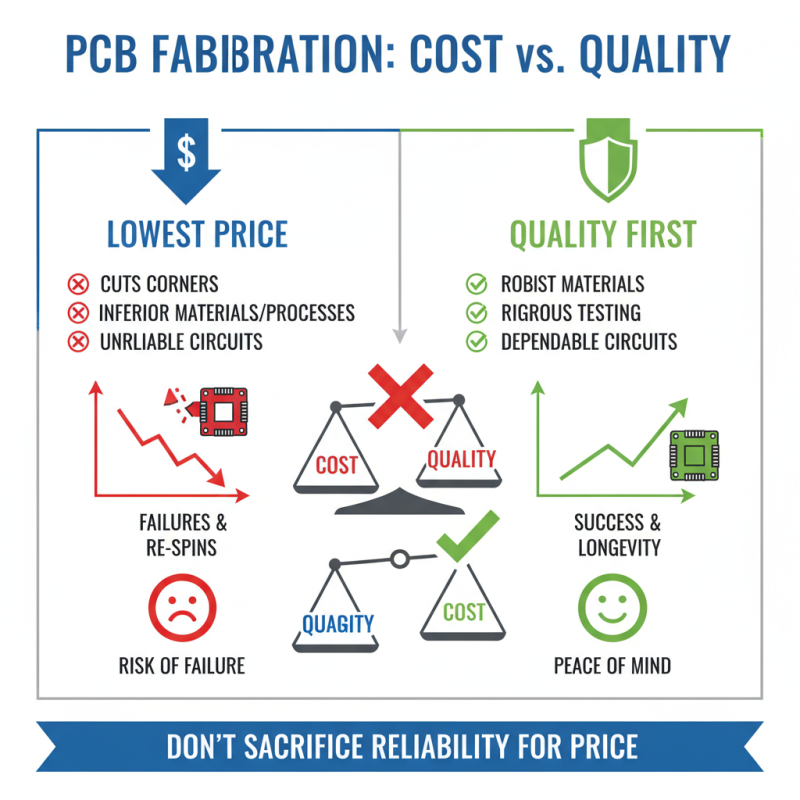

When choosing a PCB fabrication service, cost is often a primary concern. Many customers look for the lowest price. However, this approach can lead to lower quality. Inexpensive options may cut corners in material or processes. This often results in unreliable circuits. Sometimes, cheaper services may deliver boards that fail inspections. Quality should never be sacrificed for a lower price.

Analyzing cost factors is essential for effective decision-making. Many variables affect PCB pricing. These include the complexity of the design, the number of layers, and material types. Thinner traces and smaller pads may increase costs. Customers must weigh these details carefully. A low-cost PCB may save money upfront but endanger long-term performance. Reflecting on past experiences can provide valuable insight. Have cheaper boards led to more repairs? Balancing price with quality ensures a more reliable product. That’s truly the goal of any project.

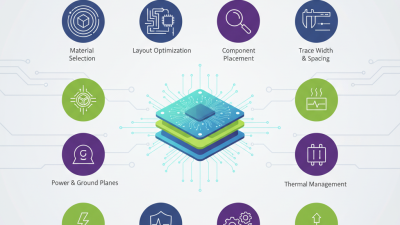

When selecting a PCB fabrication and assembly service, one must assess their technical capabilities. The layer count of a PCB significantly affects its complexity. A simple board may need just one or two layers. However, multi-layer boards can accommodate more features and advanced circuitry. Knowing your project's requirements will help in this area.

Material selection also plays a crucial role. Different types of substrates have unique properties. For instance, FR-4 is commonly used for standard applications, but advanced projects might require high-frequency materials. It is essential to discuss this with potential service providers. Ask about their capabilities in working with various materials.

Tolerances should not be overlooked. Each project has specific tolerance needs. Some projects may tolerate looseness, while others require precision. Understanding these details upfront can help avoid miscommunication. Sometimes, services might overpromise capabilities. It’s wise to verify their experience with similar projects. Don't hesitate to ask for references or examples of past work. This can provide insight into their actual capabilities.

| Service Feature | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Layer Count | 2 Layers | 4 Layers | 6 Layers |

| Material Types | FR-4 | CEM-1 | High-Frequency |

| Tolerances | ± 0.1 mm | ± 0.075 mm | ± 0.05 mm |

| Minimum Hole Size | 0.3 mm | 0.2 mm | 0.1 mm |

| Surface Finish | HASL | ENIG | OSP |

Selecting a PCB fabrication and assembly service is critical for any project. Communication is a key factor in this choice. It ensures that your needs are understood. A study indicated that 70% of project delays arise from poor communication. Be clear about your requirements. Ask potential providers about their processes and responsiveness.

Support is essential. Look for services that offer technical assistance throughout your project. Only 40% of manufacturers provide sufficient support during assembly and design phases, according to industry surveys. Inquire about their feedback mechanisms. Are there dedicated contacts for resolving issues?

Turnaround times matter too. The average lead time in PCB assembly can range from days to weeks. Understanding their capacity ensures you meet deadlines. A tip: request realistic timelines and check their past performance. Recognize that not all timelines are met, and some may lack transparency. This is where clear, open communication is vital. Choose wisely.