In the rapidly evolving landscape of modern technology, circuit board design has emerged as a critical component driving innovation and efficiency across various industries. According to a report by Grand View Research, the global printed circuit board (PCB) market is expected to reach $94.4 billion by 2025, reflecting the increasing reliance on advanced circuit board design in everything from consumer electronics to complex aerospace systems.

As electronic devices become more sophisticated, the demand for highly integrated and reliable circuit boards is paramount. This has led to advancements in design techniques, materials, and manufacturing processes, enabling engineers to create boards that not only meet performance standards but also accommodate miniaturization and multifunctionality. Understanding the intricacies of circuit board design is essential for professionals aiming to stay at the forefront of technology development and implementation.

As electronic devices become more sophisticated, the demand for highly integrated and reliable circuit boards is paramount. This has led to advancements in design techniques, materials, and manufacturing processes, enabling engineers to create boards that not only meet performance standards but also accommodate miniaturization and multifunctionality. Understanding the intricacies of circuit board design is essential for professionals aiming to stay at the forefront of technology development and implementation.

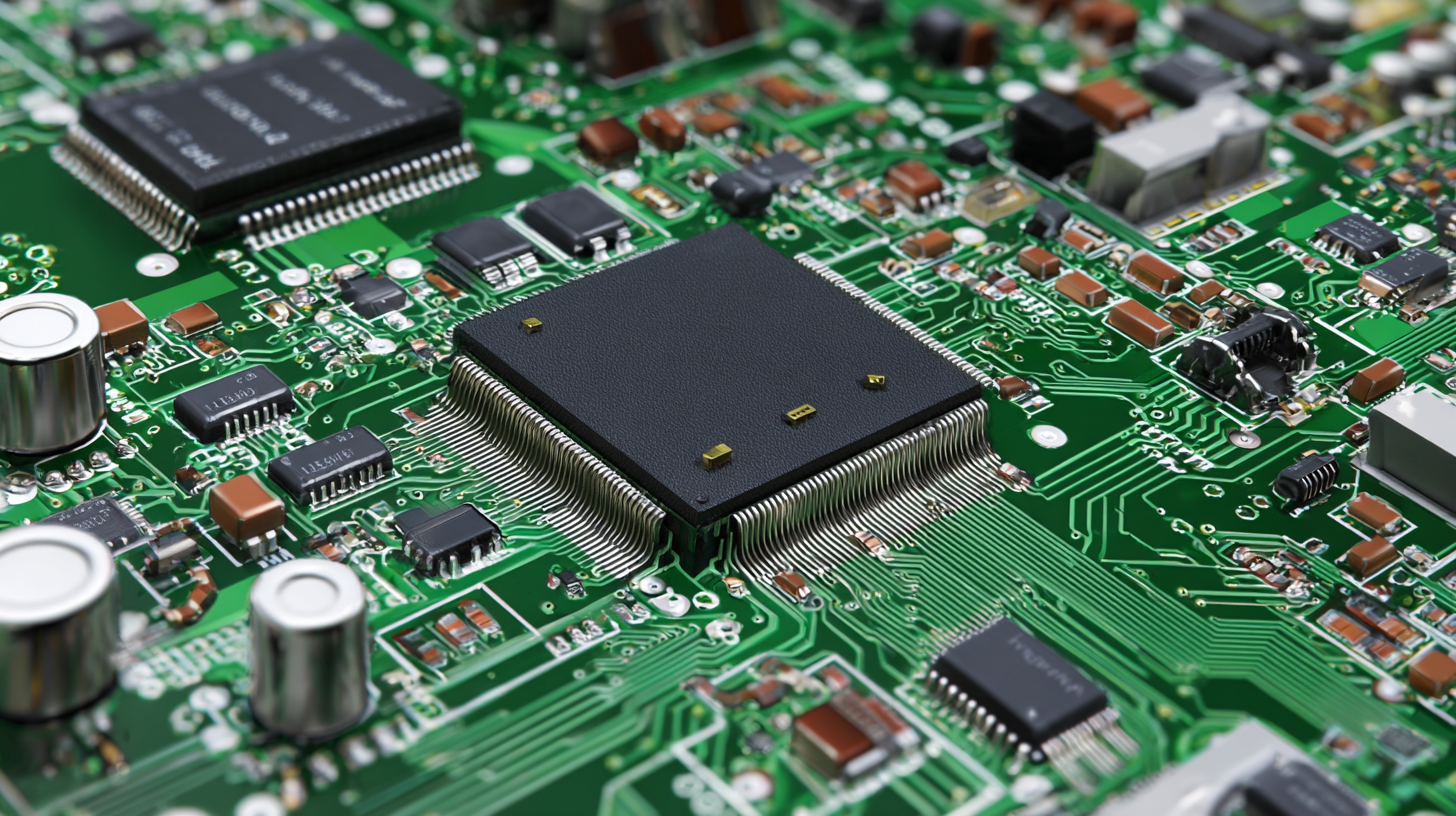

Circuit board design is a crucial aspect of modern electronics, serving as the backbone for a myriad of devices we use daily. Understanding the fundamentals of circuit board design begins with grasping the core components that make up a circuit board, including resistors, capacitors, and integrated circuits. These components are carefully arranged on a substrate, typically made from materials like fiberglass or epoxy resin, to create electrical pathways that connect different parts of a device. The layout must be meticulously planned to ensure optimal performance, minimizing interference and maximizing efficiency.

Moreover, circuit board design involves specific techniques such as schematic capture and layout design. Schematic capture allows designers to visualize the electrical connections in a circuit before they are physically implemented. In contrast, layout design focuses on the physical placement of components on the board, considering factors like signal integrity and thermal management. With the rise of sophisticated software tools, designers can simulate circuit behavior, making it easier to identify potential issues early in the design process. This foundational knowledge enables engineers to innovate and create more advanced technologies, driving the evolution of consumer electronics, medical devices, and more.

| Dimension | Description | Importance |

|---|---|---|

| Layer Count | Refers to the number of conductive layers in a circuit board. | More layers can reduce size and improve performance. |

| Material Type | The substrate material used like FR4 or polyimide. | Determines thermal and electrical properties. |

| Trace Width | Width of the conductive paths on the PCB. | Affects current carrying capacity and resistance. |

| Vias | Plated holes that allow signal connection between layers. | Essential for multi-layer circuit designs. |

| Solder Mask | Protective layer over the PCB that prevents solder bridging. | Enhances durability and reliability of the board. |

Circuit boards are the backbone of modern technology, enabling the functionality of everything from smartphones to complex industrial machines. At the core of circuit board design are several key components, each playing a vital role in ensuring efficient operation. These components include resistors, capacitors, inductors, diodes, and integrated circuits. According to a report by the IPC (Association Connecting Electronics Industries), the global market for circuit boards is expected to reach $75 billion by 2025, reflecting the rising demand for sophisticated electronics.

Resistors control the flow of electric current, preventing overloads and protecting sensitive components. Capacitors store and release electrical energy, smoothing out fluctuations in power supply. Inductors, on the other hand, are used for filtering signals and managing energy flow in power applications. Integrated circuits combine multiple functions into a single chip, greatly enhancing efficiency and reducing space requirements. The increasing complexity of devices implies a higher demand for effective circuit board design, which is expected to grow by 6% annually over the next few years.

Tips: When designing a circuit board, always consider the thermal management of components. High temperatures can lead to failures; thus, incorporating heat sinks or proper ventilation can greatly improve longevity. Additionally, prototyping your design can help identify potential flaws before the final production phase.

The evolution of circuit board design is significantly fueled by advanced software tools that streamline the process for engineers and hobbyists alike. With the growing demand for smaller, more efficient electronics, innovative software has become essential in simplifying and enhancing PCB designs. Recent trends highlight a surge in accessible PCB design software, with various platforms offering free or low-cost solutions aimed at democratizing design capabilities for students, small to mid-sized businesses, and individual creators.

Additionally, the incorporation of artificial intelligence within PCB design software is revolutionizing traditional workflows. AI-driven tools not only improve automation in design processes, but they also enable users to create highly optimized layouts rapidly. The growing accessibility of these advanced tools, amid regulatory challenges and industry shifts, ensures that engineers have the resources they need to tackle modern electronic design challenges effectively.

As the landscape continues to evolve, it is clear that software tools remain pivotal in shaping the future of circuit board design and, consequently, the technology we rely on daily.

Circuit board design is facing an array of challenges that can impact the performance and reliability of modern technologies. One of the notable issues is the integration of high-speed interconnects, particularly with the advent of 224G PAM-4 channels. Design complexities arise due to the need for precise signal integrity and thermal management in these high-bandwidth applications. Effective cooling solutions are crucial to prevent semiconductor failure, as heat generation and power loss are significant factors that engineers must consider during the design process.

To address these challenges, innovative tools and methodologies are emerging in the industry. For instance, the application of hierarchical reinforcement learning in PCB layout automation aims to streamline the design process, making it more efficient and less prone to errors. Moreover, AI-driven platforms are starting to transform the landscape by simplifying the intricate design requirements. Companies are now deploying AI to enhance Electronic Design Automation (EDA) workflows, allowing engineers to focus on solving high-level design problems rather than getting bogged down by routine complexities. As circuit board design continues to evolve, these advancements offer promising solutions to the pressing challenges faced by engineers.

The global printed circuit board (PCB) market is poised for significant growth, valued at approximately $69.69 billion in 2023 and projected to reach $113.49 billion by 2032. This growth is largely fueled by the increasing demand for smaller, more powerful, and feature-rich electronic devices. As the electronics industry witnesses a transformation driven by miniaturization, the design of printed circuit boards is evolving to enhance efficiency and reliability in various applications, particularly in aerospace and defense sectors.

Miniaturization of circuit boards is not only a trend but a necessity in modern technology integration. As devices become smaller, the complexity of PCB design increases, prompting innovations that allow for high-density interconnection and improved thermal management. The aerospace and defense PCB market, in particular, is expected to see substantial shifts by 2032, reflecting the growing reliance on advanced technology in these critical sectors. Companies are adapting to these changes by adopting new materials and design methodologies to optimize performance while ensuring robustness and sustainability in their PCB solutions.