In the ever-evolving landscape of electronics, understanding the fundamentals of circuit board manufacturing is crucial for both novices and seasoned professionals alike. With the global printed circuit board (PCB) market projected to reach approximately $90 billion by 2025, the demand for well-manufactured PCBs continues to escalate (Research and Markets, 2021). As technology advances, the complexity of circuit board designs increases, necessitating a firm grasp of manufacturing processes. From material selection to fabrication techniques, the journey of circuit board manufacturing involves meticulous planning and execution. This guide aims to demystify the key concepts and practices within the field, providing beginners with the foundational knowledge needed to navigate this essential component of modern electronic devices.

The materials used in circuit board manufacturing are crucial for determining both performance and durability. The most common material is FR-4, a glass-reinforced epoxy laminate. FR-4 provides excellent mechanical strength and heat resistance, making it a preferred choice for a wide range of applications. However, variations in its thickness and copper foil can significantly influence the electrical properties, impacting signal integrity in high-speed circuits.

Another important material is polyimide, known for its high thermal stability and flexibility, particularly in flexible printed circuit boards (FPCBs). This makes polyimide ideal for applications where bending and twisting are common, such as in wearable technology. Additionally, materials like aluminum and copper are often used for their conductive properties. Aluminum provides an effective heat dissipation option, while copper remains the standard for electrical conduction, balancing cost and performance in most circuit designs. Understanding these materials and their properties is essential for anyone looking to delve into the world of circuit board manufacturing.

| Material Type | Properties | Common Applications | Cost Range (per sq ft) |

|---|---|---|---|

| FR-4 | High dielectric strength, flame retardant | Consumer electronics, telecommunications | $2 - $5 |

| CEM-1 | Low cost, good thermal properties | Single-sided PCBs, low-tech applications | $1 - $3 |

| Polyimide | High thermal stability, flexible | Flexible circuits, aerospace applications | $10 - $20 |

| Rogers | Low loss, high-frequency performance | RF/microwave applications | $30 - $60 |

| Alumina | High thermal conductivity, insulation | High-power applications | $20 - $40 |

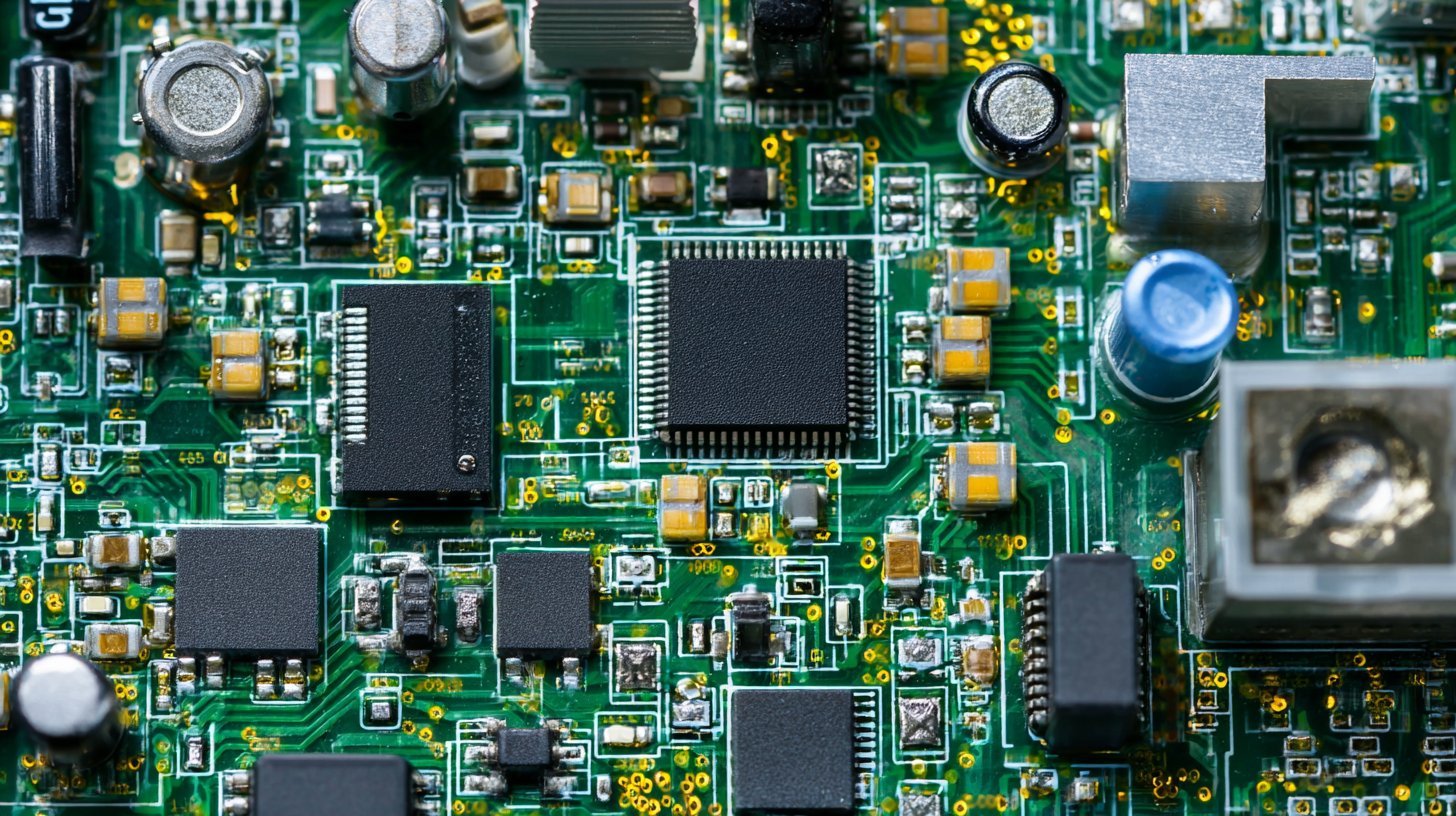

In the realm of circuit board manufacturing, having the right tools and equipment is vital for ensuring high-quality production. Essential tools include soldering equipment, which plays a crucial role in connecting electronic components to the circuit boards. The soldering equipment market is projected to expand significantly in the coming years, reflecting the growing demand for precision and reliability in electronic applications.

Moreover, understanding the various types of machinery used in circuit board manufacturing is crucial for beginners. Equipment such as precision drills, surface mount technology (SMT) machines, and PC board cutters are indispensable for achieving accuracy and efficiency in the manufacturing process. As the industry anticipates substantial growth, driven by advancements in technology and rising market values, having access to the latest tools will empower manufacturers to meet increasing demands and produce cutting-edge electronic devices.

Designing a circuit board layout is an essential process in electronics manufacturing and requires careful planning and execution. The first step involves conceptualizing the circuit's schematic, which provides a visual representation of the electronic components and their connections. Software tools such as CAD programs are commonly used to create these schematics, enabling designers to organize and visualize their circuit before moving to the layout stage.

Once the schematic is complete, the next phase is to translate this information into a physical layout. This involves placing the components on the board, typically starting with the most complex parts. Designers need to ensure that the components are positioned for optimal performance, minimizing issues such as signal interference and heat dissipation. After placement, traces are drawn to connect the components, following best practices for signal integrity and manufacturability. Throughout this step, iterative testing and adjustments are crucial to develop an efficient and functional final product.

Circuit board manufacturing is a complex process involving various techniques that ensure the reliable assembly of electronic components. One common method is the etching process, where a copper-clad laminate is coated with a photosensitive material. After exposure to ultraviolet light, unwanted copper is removed, leaving behind pathways that connect different components. This technique is fundamental in defining the circuit layout, as it allows for precise control over the final design.

Another essential technique is surface mount technology (SMT), which involves placing components directly onto the surface of the circuit board. SMT has gained popularity due to its efficiency and the ability to accommodate smaller components, leading to more compact devices. Solder paste is applied to the pads on the board, and components are accurately placed before being soldered in a reflow oven, ensuring strong electrical connections. Combination of these methods is critical in achieving high-quality circuit boards that meet modern electronic demands.

Quality control is a critical aspect of circuit board manufacturing, ensuring that products meet specified standards and function reliably in their intended applications. Implementing stringent measures throughout the production process not only minimizes defects but also enhances overall product performance and durability. Recent advancements in artificial intelligence have significantly transformed quality assurance practices, allowing for real-time monitoring and analysis of production metrics. This technology facilitates the early detection of potential defects, thereby reducing waste and costly rework.

In the domain of circuit board manufacturing, companies are increasingly leveraging deep learning frameworks to improve defect classification and detection. This innovative approach utilizes object detection models to identify and categorize defects swiftly, ensuring that only high-quality boards reach the market. Such efforts are vital, especially in sectors like automotive and defense, where the reliability of circuit boards can have critical implications. Moreover, the introduction of AI tools simplifies the quality assessment of raw materials, promoting better manufacturing practices and leading to the development of more advanced electronic devices.