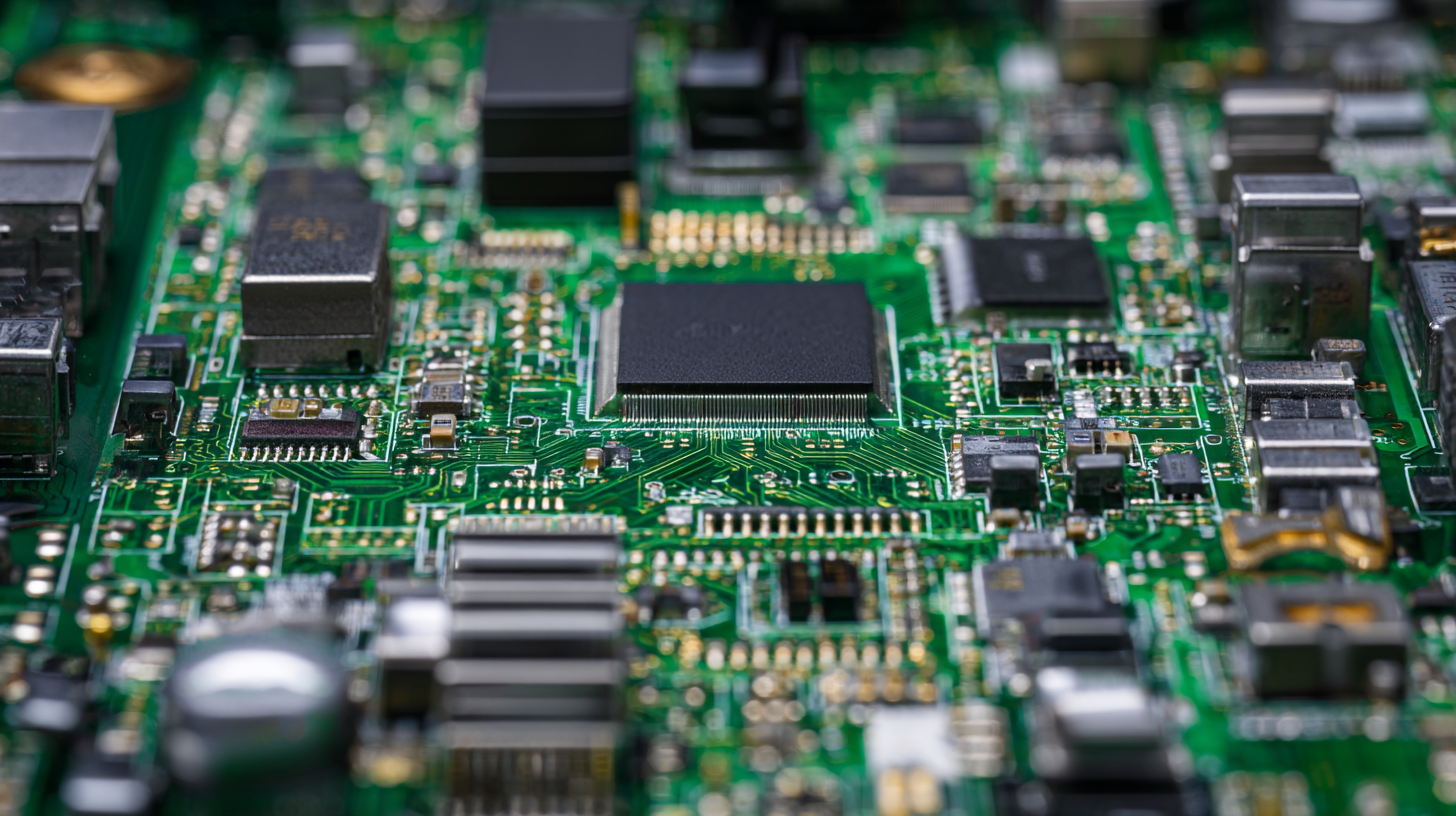

The evolution of PCB circuit boards has been a pivotal aspect of technological advancement, significantly influencing the design and functionality of electronic devices over the past few decades. As we delve into the intricate journey of these essential components, it becomes evident that innovations in materials, manufacturing processes, and design methodologies have continually reshaped the landscape of circuit board technology. This exploration not only highlights the historical milestones that have defined the development of PCB circuit boards but also projects future innovations that promise to revolutionize electronic applications. By understanding the past trends and breakthroughs, we can better appreciate the potential advancements on the horizon, addressing challenges such as miniaturization, increased efficiency, and environmental sustainability. Ultimately, this analysis underscores why PCB circuit boards remain at the forefront of electronic engineering, driving both current and future innovations in the tech industry.

The journey of printed circuit board (PCB) technology has been marked by significant milestones that have shaped its evolution. The invention of PCBs can be traced back to the early 20th century, with significant advancements occurring in the 1940s and 1950s when the first PCBs were used in military applications during World War II. This period marked the transition from traditional point-to-point wiring to the more efficient and reliable PCB design, which greatly reduced assembly times and improved operational efficiency.

In the 1960s and 1970s, the proliferation of consumer electronics accelerated the demand for PCBs, leading to innovations such as multilayer boards and the development of surface-mount technology (SMT). According to a report by the IPC (Association Connecting Electronics Industries), global PCB shipments reached approximately $64 billion in 2020, showcasing the fundamental role of PCBs in the modern electronics industry. As technology continues to advance, we see continuous efforts to enhance PCBs with new materials and designs, including flex and rigid-flex circuits, further expanding their applications in sectors such as aerospace and medical devices. The evolution of PCB technology not only highlights its historical significance but also points towards a future filled with innovations tailored to meet the demands of an increasingly interconnected world.

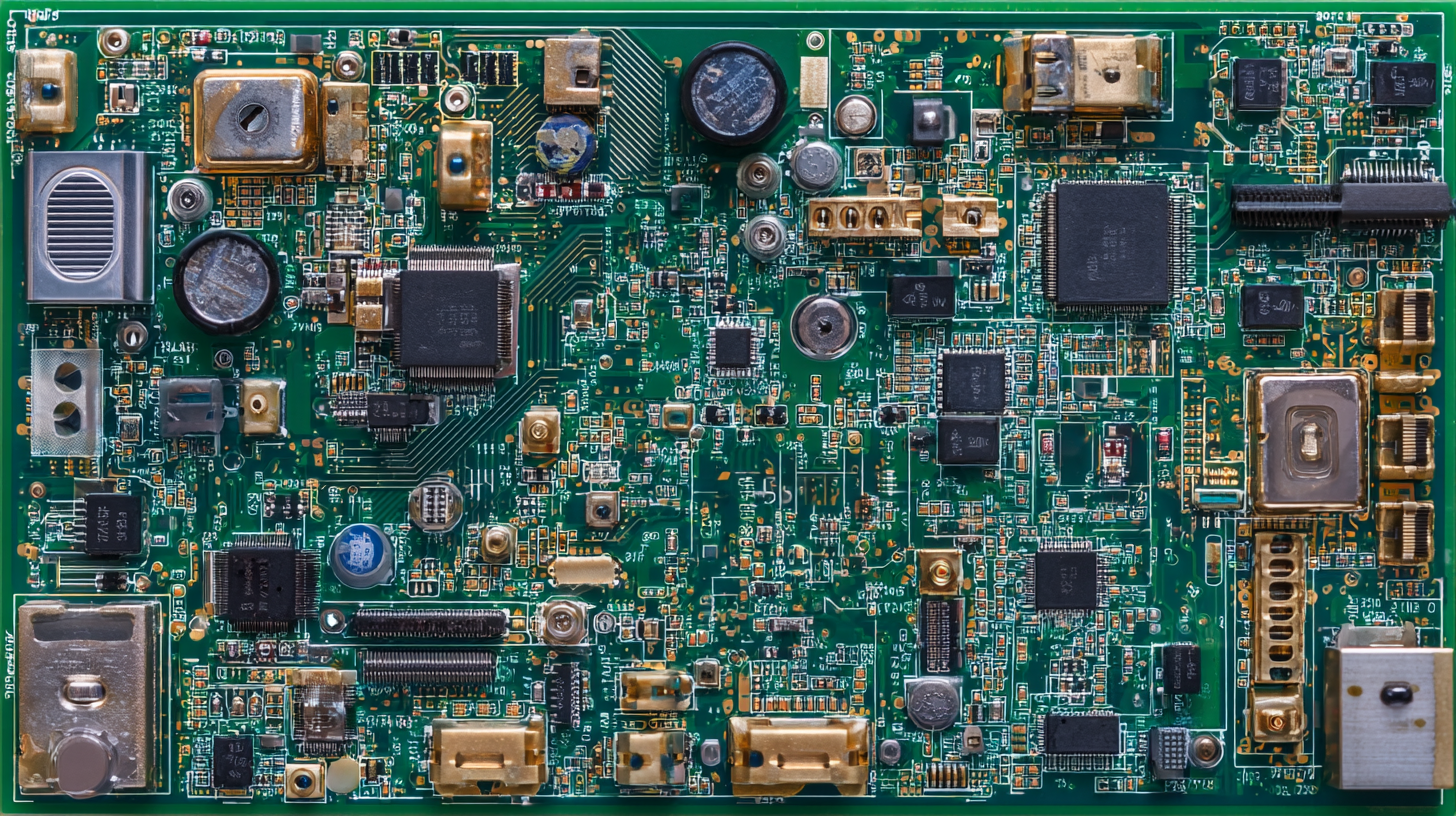

The evolution of PCB (Printed Circuit Board) technology has been significantly influenced by various key innovations. Among these, the move towards higher layer counts and the integration of advanced materials has transformed modern PCB design and manufacturing. According to a report by MarketsandMarkets, the global PCB market is projected to reach USD 88.22 billion by 2025, driven by the demand for miniaturization and enhanced functionality in electronic devices. Innovations such as HDI (High-Density Interconnect), flexible PCBs, and embedded components have allowed manufacturers to create smaller, lighter, and more efficient circuit boards that meet the increasing demands of applications in telecommunications, automotive, and consumer electronics.

Tip: When selecting PCB materials, consider their thermal stability and dielectric properties, as these factors play a crucial role in the performance of high-frequency applications. Additionally, advancements in manufacturing processes, such as additive manufacturing and automated assembly, have significantly shortened production times and improved precision. These processes not only reduce costs but also open avenues for more complex designs that were previously challenging to achieve.

Tip: Stay updated on industry trends and best practices for PCB design, as incorporating new technologies can lead to substantial performance gains and cost savings. As the PCB industry continues to evolve, embracing these innovations will be vital for businesses seeking to maintain a competitive edge and meet the demands of future electronic systems.

The integration of digital technologies into PCB circuit boards represents a significant turning point in electronics manufacturing. As per the latest report from MarketsandMarkets, the global PCB market is projected to reach $76.9 billion by 2026, driven by the demand for smart devices and IoT applications. Advanced features, such as embedded components and flexible circuits, are now standard, leading to improved performance and reduced space in electronic designs.

Tips for engineers looking to implement these technologies include investing in simulation software to optimize designs before fabrication, which can decrease costs and development time. Additionally, adopting digital twin technology can help in real-time monitoring and predictive maintenance of PCB assemblies, enhancing efficiency and reliability in production.

The rise of Industry 4.0 further accelerates the adoption of smart PCBs that utilize sensors and data analytics. According to a recent study by Research and Markets, smart PCB systems could account for over 25% of the PCB market share by 2025. To stay competitive, manufacturers should consider integrating AI and machine learning in their design processes to foster innovation and adaptability in their circuit board applications.

| Dimension | Current Status | Future Innovation | Impact of Digital Technologies |

|---|---|---|---|

| Design Tools | Manual CAD tools with limited automation. | Advanced AI-driven design automation. | Improved accuracy and efficiency in design. |

| Manufacturing Processes | Conventional manufacturing techniques. | 3D Printing and additive manufacturing. | Reduction in material waste and faster prototyping. |

| Testing and Quality Control | Manual testing with limited analytics. | Automated testing with real-time data analysis. | Enhanced reliability and reduction in failure rates. |

| Supply Chain | Traditional supply chain management. | Blockchain for transparency and traceability. | Increased trust and efficiency in procurement. |

| Product Lifespan | Standard product lifecycle management. | IoT integration for predictive maintenance. | Prolonged usage and reduced downtime. |

The field of PCB technology is witnessing transformative changes driven by the increasing demand for flexibility and miniaturization in applications across various industries.

Flexible printed circuit boards (FPCBs) are gaining traction due to their adaptability, allowing manufacturers to design complex circuits that can fit into compact spaces and conform to various shapes. This has made FPCBs particularly valuable in industries like consumer electronics, automotive, and medical devices, where lightweight and space-saving solutions are paramount.

Miniaturization is another significant trend in PCB development, propelled by advancements in microelectronics and the Internet of Things (IoT). As devices shrink in size, PCBs must evolve to accommodate high-density components without compromising performance.

Techniques such as multi-layer PCB designs and advanced materials are being employed to achieve this goal, enabling smaller devices to offer enhanced functionality. The combination of flexibility and miniaturization not only meets current consumer demands but also paves the way for future innovations, allowing for more sophisticated applications in emerging fields such as wearable technology and autonomous systems.

The future of printed circuit boards (PCBs) is set to be transformed by sustainable practices and the advent of smart technologies. As industries increasingly focus on reducing their environmental impact, the demand for sustainable manufacturing methods is rising. Innovations such as flexible PCBs (FPCs), which offer superior performance and reliability while utilizing eco-friendly materials, highlight the importance of sustainability in PCB design. This trend aligns with broader goals across various sectors to adopt practices that minimize waste and promote recyclability.

Additionally, the integration of smart technologies into PCBs is creating new opportunities for functionality and efficiency. As artificial intelligence (AI) continues to drive advancements in various fields, its application in PCB design and manufacturing is paving the way for intelligent circuit boards that can optimize performance and reduce energy consumption. The combination of AI with sustainable practices not only enhances the capabilities of PCBs but also aligns with global efforts towards a greener future. As technology continues to evolve, the PCB industry is poised to embrace these innovations, ensuring its relevance and competitiveness in the marketplace.