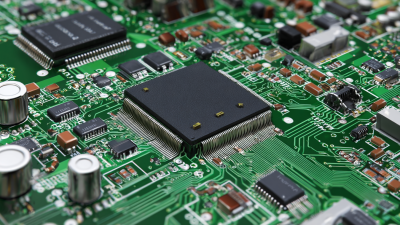

The landscape of PCB circuit board technology is rapidly evolving, driven by innovations in design and manufacturing processes that aim to enhance performance, reliability, and sustainability. According to a recent report by MarketsandMarkets, the global PCB market is expected to reach USD 83.2 billion by 2025, growing at a CAGR of 4.9% from 2020 to 2025. This growth is largely attributed to the increasing demand for advanced electronic devices, automotive electronics, and the expansion of the Internet of Things (IoT). As we explore the future of PCB circuit boards, it is essential to consider the advancements in techniques such as additive manufacturing, flexible PCB designs, and eco-friendly materials, which not only improve functionality but also minimize environmental impact. The integration of these innovations is paving the way for smarter, more efficient electronics that meet the demands of an increasingly interconnected world.

The landscape of PCB circuit board technology is rapidly evolving, driven by innovations in design and manufacturing processes that aim to enhance performance, reliability, and sustainability. According to a recent report by MarketsandMarkets, the global PCB market is expected to reach USD 83.2 billion by 2025, growing at a CAGR of 4.9% from 2020 to 2025. This growth is largely attributed to the increasing demand for advanced electronic devices, automotive electronics, and the expansion of the Internet of Things (IoT). As we explore the future of PCB circuit boards, it is essential to consider the advancements in techniques such as additive manufacturing, flexible PCB designs, and eco-friendly materials, which not only improve functionality but also minimize environmental impact. The integration of these innovations is paving the way for smarter, more efficient electronics that meet the demands of an increasingly interconnected world.

The shift towards flexible PCB designs is reshaping the landscape of electronic manufacturing, offering substantial advantages in various applications. According to a report by IDTechEx, the global market for flexible PCBs is projected to reach $34 billion by 2026, driven by advancements in technology and increasing demand for compact, lightweight devices. This trend is particularly significant in consumer electronics, where the integration of flexible circuit boards allows for innovative product designs that can bend and conform to various shapes, enhancing usability and portability.

Flexible PCBs also find extensive applications in medical devices and wearables, where miniaturization and adaptability are crucial. The ongoing research from MarketsandMarkets indicates that the flexible circuit market is expected to grow at a CAGR of 12.8% between 2021 and 2026, highlighting the rising importance of these designs in sectors that require flexibility and reliability. For instance, in wearable health monitors, the ability to create snugly fitting electronics can lead to more accurate data collection and improved user experience. Overall, innovative flexible PCB designs are not only optimizing space and efficiency but are also paving the way for the next generation of electronics, catering to the ever-evolving needs of various industries.

The integration of automation and artificial intelligence (AI) into PCB manufacturing is revolutionizing the industry, driving efficiency and enhancing product quality. According to a report by Transparency Market Research, the global PCB market is projected to reach USD 80 billion by 2025, with AI and automation solutions playing a crucial role in this growth. Automated systems can streamline production lines, significantly reducing human error and increasing throughput. This shift not only minimizes costs but also accelerates the time-to-market for new designs.

Moreover, AI technologies are enabling smarter design processes through predictive analytics and machine learning algorithms. A study by ResearchAndMarkets indicates that AI can reduce design cycle times by up to 30%. By analyzing vast amounts of data, AI tools can suggest optimal layout configurations and identify potential manufacturing issues before they arise. This proactive approach ensures higher reliability and performance of PCB products, aligning with the growing demands for miniaturization and functional integration in electronic devices. As companies embrace these emerging technologies, the future of PCB circuit boards looks promising, marking a significant leap towards more efficient and innovative manufacturing processes.

The push for sustainability in PCB (Printed Circuit Board) production is increasingly reshaping the industry landscape. According to a report by Transcend Reports, the global market for eco-friendly PCB materials is expected to grow at a CAGR of 10.3% between 2021 and 2026. This surge reflects the industry's urgent shift towards adopting biocompatible materials and reducing harmful waste outputs. Manufacturers are now exploring alternatives such as recyclable substrates and environmentally friendly laminates, which significantly lower the ecological footprint of PCB production.

Moreover, innovative processes such as laser direct structuring and additive manufacturing are contributing to enhanced sustainability in PCB design and production. Industry sources indicate that using additive manufacturing can reduce material waste by over 90% compared to traditional subtractive methods. This not only conserves resources but also allows for more complex and customized designs that meet the growing demands for compact and efficient electronic devices. As the industry continues to innovate, the integration of sustainable practices is not just a trend; it is becoming a fundamental requirement to meet regulatory standards and consumer expectations for greener electronics.

Moreover, innovative processes such as laser direct structuring and additive manufacturing are contributing to enhanced sustainability in PCB design and production. Industry sources indicate that using additive manufacturing can reduce material waste by over 90% compared to traditional subtractive methods. This not only conserves resources but also allows for more complex and customized designs that meet the growing demands for compact and efficient electronic devices. As the industry continues to innovate, the integration of sustainable practices is not just a trend; it is becoming a fundamental requirement to meet regulatory standards and consumer expectations for greener electronics.

The rapid evolution of technology has significantly influenced advancements in PCB testing methods, leading to improved quality and reliability in circuit boards. Modern testing techniques, such as Automated Optical Inspection (AOI), X-Ray Inspection, and In-Circuit Testing (ICT), enable manufacturers to detect potential defects early in the production process. This proactive approach not only ensures operational efficiency but also reduces costly reworks and guarantees the end product’s performance in demanding applications.

**Tip:** Implementing a comprehensive testing strategy should include both functional and structural tests to cover all potential failure points. Regular updates to testing equipment and methodologies can greatly enhance accuracy and effectiveness.

With ongoing innovations, manufacturers are increasingly turning to AI and machine learning to analyze testing data for predictive insights. These technologies help in identifying patterns in failures, thereby facilitating timely adjustments in design and manufacturing. Enhanced testing methods are not only crucial for meeting regulatory standards but also for building consumer confidence in electronics reliant on PCB technology.

**Tip:** Consider regular training for your testing teams on the newest technologies and procedures, as keeping up with industry best practices can help maintain a competitive edge.

| Dimension | Description | Current Trends | Future Directions |

|---|---|---|---|

| Design Innovations | Enhanced simulation and modeling tools for PCB design. | Increased use of AI and machine learning in design processes. | Integration of smart design techniques to optimize layouts. |

| Manufacturing Processes | Adoption of flexible manufacturing systems and automation. | Use of advanced materials like flexible substrates and multilayer boards. | Increased use of 3D printing in PCB production. |

| Testing Methods | Methods for functional testing, including in-circuit testing. | Migration towards automated optical inspection (AOI) systems. | Implementation of AI for predictive maintenance of testing equipment. |

| Quality Assurance | Focus on enhancing reliability and durability in design. | Utilization of real-time monitoring throughout production. | Development of industry standards for quality assurance. |

The advent of 5G technology and the Internet of Things (IoT) is driving a significant transformation in the design and manufacturing of PCB circuit boards. As devices become more interconnected and demand for high-speed data transmission escalates, PCBs must be engineered to accommodate greater complexity and smaller form factors. This shift challenges engineers to innovate in materials and design approaches, enabling the development of ultra-thin, high-density interconnects that can support the massive data streams associated with 5G.

Additionally, IoT devices often operate in diverse environments, demanding PCBs that are not only efficient but also durable and reliable under varying conditions. Innovations such as advanced thermal management techniques and the integration of smart technologies into PCB designs are becoming essential. These advancements will ensure that circuit boards can handle the demands of real-time data processing and edge computing, allowing IoT devices to function effectively and sustainably in the expanding digital ecosystem. As a result, the synergy between PCB innovation and these groundbreaking technologies is set to redefine the landscape of electronics manufacturing.