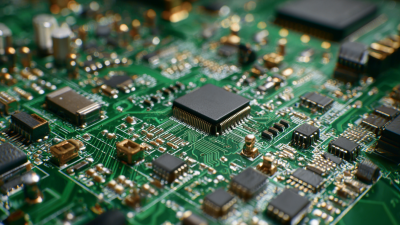

The global PCB manufacturing and assembly market is witnessing remarkable growth, driven by innovations in technology and the increasing demand for electronic devices. According to a report by ResearchAndMarkets, the PCB market is projected to reach USD 85 billion by 2027, growing at a CAGR of approximately 3.7% from 2020 to 2027. This surge is fueled by advancements in automation and the growing complexity of electronic circuits, which necessitate a deeper understanding of PCB manufacturing and assembly processes. For beginners venturing into this intricate field, it is crucial to grasp the foundational principles and practices that underlie successful PCB fabrication and integration. From understanding the various materials used in production to mastering assembly techniques, this comprehensive guide will unlock the secrets of PCB manufacturing and assembly, equipping newcomers with the knowledge needed to navigate this dynamic industry effectively.

PCB design is a fundamental aspect of electronics, serving as the backbone for virtually all electronic devices. According to a report by IPC, the global PCB market is projected to reach $82 billion by 2026, driven by the rapid advancements in technology and increasing demand for consumer electronics. Understanding the basics of PCB design not only enhances the performance and reliability of electronic products but also significantly impacts production efficiency and cost-effectiveness.

The importance of PCB design extends into various sectors, including automotive, telecommunications, and medical devices. A well-designed PCB can reduce the risk of malfunctions and optimize signal integrity. In a study conducted by the IEEE, it was found that 70% of all electronic failures can be traced back to poor PCB design practices. Therefore, investing time in understanding the principles of PCB layout, component placement, and signal routing is essential for anyone entering the electronics field. This foundational knowledge is critical for creating efficient and functional electronic circuits that meet the evolving technological demands of our world.

When diving into PCB manufacturing, the material selection process is critical to ensuring the final product meets performance and reliability standards. According to a report by IPC, the global market for PCBs was projected to reach $74 billion by 2024, driven primarily by advancements in materials technology that enhance electrical performance and reduce manufacturing costs. High-frequency laminates, such as PTFE (Polytetrafluoroethylene), and rigid-flex materials are increasingly favored for their unique properties, making them essential for applications in telecommunications and aerospace.

Once materials are selected, the production processes, including photoengraving, etching, and solder mask application, take center stage. Each process requires precision and quality control to minimize defects. A study by the Electronics Industry Association noted that the average defect rate for PCBs can be as high as 15%, highlighting the importance of employing thorough testing methods like Automated Optical Inspection (AOI) and X-ray inspection to identify flaws early in production. This meticulous approach not only ensures higher yield rates but also enhances the durability and functional integrity of the final PCB assemblies.

When diving into the world of PCB (Printed Circuit Board) assembly, understanding key components and their roles is crucial for beginners. Essential elements such as resistors, capacitors, inductors, and ICs (Integrated Circuits) play distinct functions in a circuit. For instance, resistors limit current flow, capacitors store and release electrical energy, and inductors manage electromagnetic fields. According to a report by IPC, the global PCB market is predicted to reach approximately $75 billion by 2025, reflecting the significance of these components in the electronics industry.

Tip: Familiarize yourself with software tools used for PCB design, like Altium Designer or Eagle, to help you visualize how these components interact on a board. Understanding the layout and schematic will deepen your knowledge of PCB functionality.

Furthermore, each component's specifications, such as tolerance and power rating, are crucial for ensuring the overall reliability of the PCB design. Missing these details can lead to failures in circuit operation. Research from Research and Markets indicates that a well-optimized assembly process can enhance efficiency by up to 30%, underscoring the importance of component selection and placement.

Tip: Always double-check component specifications against your design to avoid common pitfalls that could lead to costly rework.

| Component | Role in PCB Assembly | Common Types | Typical Applications |

|---|---|---|---|

| Resistor | Limits the flow of electrical current | Metal Film, Carbon Film, Wirewound | Voltage dividers, Signal attenuation |

| Capacitor | Stores and releases electrical energy | Ceramic, Electrolytic, Tantalum | Smoothing out voltage fluctuations, Filtering |

| Inductor | Stores energy in a magnetic field | Air Core, Iron Core, Ferrite Core | Power supply smoothing, RF circuits |

| Diode | Allows current to flow in one direction | Standard, Zener, Schottky | Rectification, Voltage regulation |

| Transistor | Amplifies or switches electronic signals | BJT, MOSFET, IGBT | Signal processing, Switching applications |

Quality control is a critical aspect of PCB manufacturing, ensuring that the final product meets industry standards and customer expectations. One essential technique is the implementation of Automated Optical Inspection (AOI), which utilizes advanced imaging technology to detect defects in PCB layouts and soldering. This method allows manufacturers to identify issues at an early stage, reducing waste and enhancing overall product reliability.

Quality control is a critical aspect of PCB manufacturing, ensuring that the final product meets industry standards and customer expectations. One essential technique is the implementation of Automated Optical Inspection (AOI), which utilizes advanced imaging technology to detect defects in PCB layouts and soldering. This method allows manufacturers to identify issues at an early stage, reducing waste and enhancing overall product reliability.

Another best practice involves rigorous testing procedures throughout the manufacturing process. This can include electrical testing to ensure that each circuit functions correctly and thermal imaging to monitor component temperatures during operation. Additionally, employing Statistical Process Control (SPC) can help manufacturers track variations in the manufacturing process, enabling them to make data-driven adjustments for consistent quality. By adopting these techniques, PCB manufacturers can significantly improve their production capabilities and reduce the risk of failures in the final assembly.

Efficient sourcing and logistics are crucial for navigating the complex PCB supply chain, especially as demand continues to rise.

According to a report by Research and Markets, the global PCB market is expected to grow at a

CAGR of 4.4%, reaching $80 billion by 2026. As a beginner in PCB manufacturing and assembly,

understanding the nuances of supplier selection and inventory management can significantly impact

production timelines and costs.

One effective strategy for efficient sourcing is to establish strong relationships with multiple suppliers. By diversifying your supplier base, you can mitigate risks associated with supply chain disruptions, as seen during the pandemic when many manufacturers faced delays due to reliance on single sources. Furthermore, utilizing tools such as

Vendor Managed Inventory (VMI) can streamline logistics and ensure timely access to essential materials. This approach not only enhances reliability but also helps in optimizing inventory levels, ultimately reducing wasted operational costs.