The world of PCB manufacturing is undergoing a transformative shift as flexible circuits emerge as a driving force within the burgeoning $60 billion market. This evolution is not merely a trend but a fundamental change in how electronic components are designed and incorporated into various applications, from consumer electronics to automotive technologies.

Flexible circuits offer unmatched advantages, including lightweight construction, space-saving designs, and enhanced reliability under dynamic conditions. As industries recognize these benefits, the demand for flexible PCB solutions is surging, leading to innovations in manufacturing processes and materials.

This introduction explores the rise of flexible circuits, examining the factors influencing this trend, the implications for the PCB manufacturing landscape, and how businesses can adapt to capitalize on this exciting new frontier in electronics.

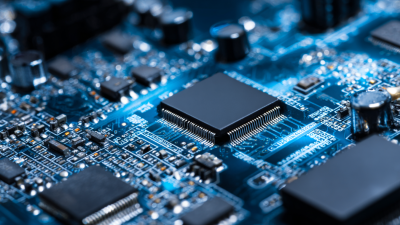

Printed Circuit Boards (PCBs) are essential components in modern electronics,

serving as the backbone for connecting various electronic elements. The manufacturing process of PCBs is intricate,

involving several key stages, including design, fabrication, assembly, and testing.

Initially, the design process utilizes computer-aided design (CAD) software to develop the layout and circuitry of the PCB.

This stage sets the foundation for the entire project, as it determines how components will interact within the electronic device.

Once the design is finalized, the fabrication process begins, typically involving techniques such as

etching, drilling, and plating.

Etching removes unwanted copper from the PCB, while drilling creates holes for component leads.

Flexible circuits are revolutionizing PCB design, providing unprecedented opportunities for innovation across various industries. With advancements in materials and manufacturing techniques, designers can now create circuits that bend, fold, and conform to complex geometries. This flexibility not only saves space but also enhances the performance and durability of electronic devices, particularly in sectors like consumer electronics, automotive, and medical technology.

Tips for embracing flexible circuits in your designs include starting with a thorough understanding of the materials involved. Polyimide and polyester are common substrates that offer excellent thermal stability and electrical performance. Additionally, collaborate closely with manufacturers early in the design phase to ensure the feasibility of your concepts and to optimize for manufacturing processes. Testing prototypes under real-world conditions can also reveal insights that guide modifications, ensuring a successful transition from concept to production.

As the market for flexible circuits continues to grow, driven by demand for lightweight, compact, and efficient electronic solutions, it is essential to stay informed about emerging technologies. Innovations such as embedded components and advanced surface mount techniques are pushing the boundaries of what flexible circuits can achieve, leading to enhanced functionality and reliability in final products. This continued evolution not only benefits manufacturers but also enhances user experience in a competitive landscape.

The flexible circuit sector is experiencing remarkable growth, driven by advancements in technology and the increasing demand for compact and efficient electronic devices. According to a recent industry report by MarketsandMarkets, the global

flexible printed circuit (FPC) market size is expected to reach approximately $33.5 billion by 2026, growing at a CAGR of 10.5% from 2021. This trend reflects the rising adoption of flexible circuits across various applications,

including consumer electronics, automotive, and medical devices, as industries seek to innovate and reduce the size of their products without compromising performance.

Furthermore, a report by Research and Markets emphasizes that the shift towards miniaturization and lightweight designs is fueling the demand for flexible circuits. As the Internet of Things (IoT) devices proliferate, manufacturers require flexible circuits that can easily accommodate

complex geometries and configurations while maintaining high reliability. The growth of the wearable technology sector also contributes significantly to this trend, with a projected market worth of $60 billion by 2025, highlighting the substantial role that flexible circuits

play in enabling new functionalities in compact forms. This dynamic interplay among technology, market demand, and innovation underscores the importance of flexible circuits in the evolving landscape of electronics manufacturing.

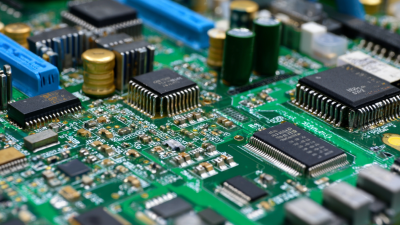

The production of flexible printed circuit boards (PCBs) is gaining momentum in a market projected to reach $60 billion. However, manufacturers face several technical challenges that can hinder the efficiency and quality of production. One primary issue is the complexity of materials used in flexible circuits. Unlike traditional rigid PCBs, flexible circuits require specialized substrates, such as polyimide or polyester, which must endure bending and twisting without compromising performance. This calls for precise material handling and advanced processes to ensure reliability under mechanical stress.

Another significant hurdle is the intricacy of manufacturing techniques. Flexible PCBs often incorporate intricate designs and components that necessitate advanced fabrication methods like laser cutting and multi-layer lamination. These processes not only require high precision but also pose challenges in maintaining consistency and reducing production costs. Moreover, the integration of components such as microchips and sensors further complicates assembly due to their sensitivity to environmental factors. Therefore, addressing these technical hurdles is essential for manufacturers aiming to leverage the growing demand for flexible circuits in various applications, from consumer electronics to medical devices.

The $60 billion PCB (Printed Circuit Board) market is poised for significant transformation as technological advancements and consumer demands evolve. With the increasing prevalence of electronics in automotive, healthcare, and consumer products, manufacturers must adapt to incorporate innovative designs and materials. Specifically, flexible circuits are gaining traction due to their ability to fit into compact spaces and their versatility in various applications. This trend signifies a shift towards more sophisticated manufacturing processes, blending both functionality and efficiency.

Tip: To stay competitive in the PCB market, companies should invest in research and development to explore new materials and manufacturing techniques. Keeping abreast of industry trends can help manufacturers anticipate shifts and meet customer expectations effectively.

As the market progresses, sustainability will also play a crucial role in shaping the future of PCB manufacturing. Eco-friendly materials and processes are becoming increasingly important, reflecting a global push toward greener electronics. Companies that prioritize sustainability will not only enhance their market appeal but also contribute positively to environmental preservation.

Tip: Implementing recycling initiatives and reducing waste in production can significantly improve a company's sustainability profile, attracting environmentally conscious consumers and businesses alike.