ACME PCB Assembly has provided (Ball Grid Array) BGA assembly, BGA rework, and BGA reballing service for Printed Circuit Boards since 1994. Having 20+ years experience behind us, we have extensive knowledge on how to assemble high quality (Ball Grid Array) BGAs. We have experience with everything from Micro BGAs to large size BGAs (55 mm), and ceramic BGAs to plastic BGAs.

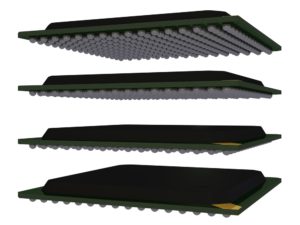

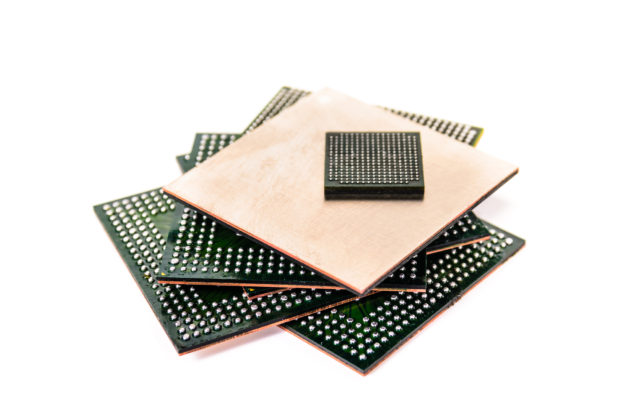

BGA assembly is a type of SMT process, which is used for Printed Circuit Boards. It allows for the customer to have more room for the PCB layout. Ball Grid Array (BGA) packaging is a method for reducing package size and integrating a greater number of functions on a single chip module. BGA (Ball Grid Array) also replaces solder balls on the component underside for SMT mounting.

BGA assembly is a type of SMT process, which is used for Printed Circuit Boards. It allows for the customer to have more room for the PCB layout. Ball Grid Array (BGA) packaging is a method for reducing package size and integrating a greater number of functions on a single chip module. BGA (Ball Grid Array) also replaces solder balls on the component underside for SMT mounting.

ACME PCB Assembly has a quality system for BGA assembly, the BGA will be received and inspected, and kept in a 40-degree Celsius storage with a 1% humility baking oven to make sure the BGA is good condition before assembly. We inspect the BGA with a 3D X-ray, and make sure the void is under 25% of the total solder ball diameter. By using the X-Ray inspection process, we can eliminate the soldering problem on the board, such as solder bridging and insufficient ball melting.

We also add an additional layer inspection after the X-Ray inspection is done; using the ERSA scope to inspect the solder ball on the underside of the BGA so that we are sure the profile is correct; we assure you excellent quality during the BGA assembly process. Some BGA assembly boards have VIA connect to the BGA pad, the best condition for that is have a VIA epoxy plug, and have the solder mask on the trace, so that solder is not wicked to the VIA and cause the solder to function insufficiently during the BGA assembly process.

By having ACME PCB Assembly do the BGA assembly prototype with or without Stencil will save you as the customer on assembly costs.

Please call us at 310-715-1898 for get more information or Assembly quotation.

Instead of using pins like traditional packages, a BGA uses an array of solder balls on the underside of the component. These balls create electrical connections during reflow soldering, improving both thermal conductivity and electrical performance. The result is a more robust, space-efficient, and reliable PCB assembly.

Instead of using pins like traditional packages, a BGA uses an array of solder balls on the underside of the component. These balls create electrical connections during reflow soldering, improving both thermal conductivity and electrical performance. The result is a more robust, space-efficient, and reliable PCB assembly. BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability.

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability.