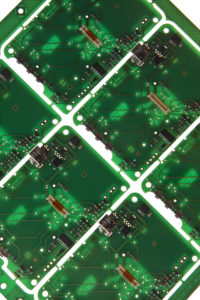

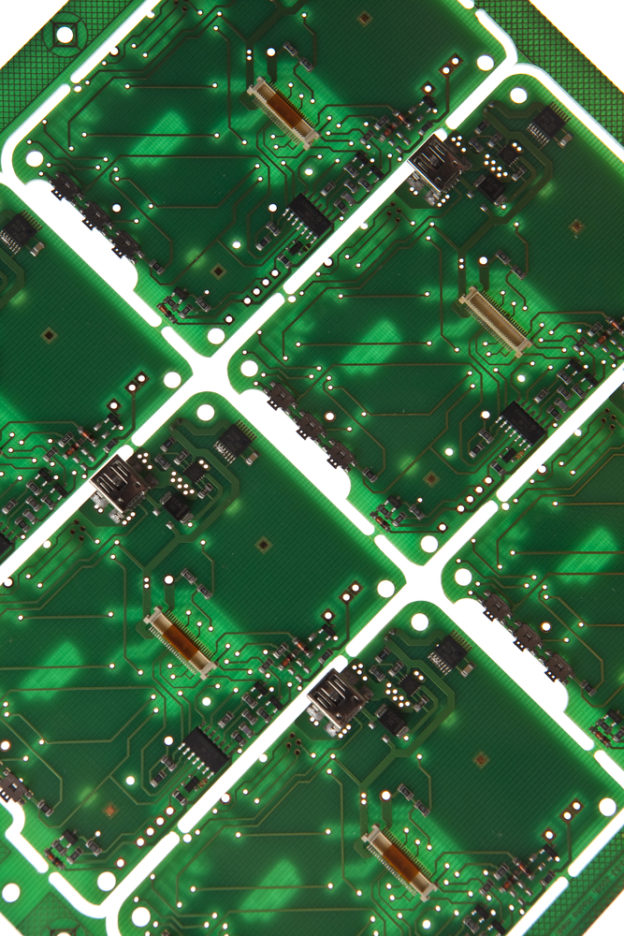

In today’s fast-paced technology landscape, using high-quality PCBs in your projects is essential for success. Printed circuit boards form the backbone of countless devices, from smartphones to industrial machines, and their performance can make or break your innovation. Ensuring that the printed circuit boards you select meet rigorous standards and are produced under stringent quality control measures is key to delivering reliable, durable, and efficient products.

When working on any tech-driven project, it’s crucial to focus on the longevity and performance of your components. High-quality PCBs offer enhanced reliability, reducing the likelihood of malfunction or failure in the field. This is especially important in industries where downtime can result in costly delays or safety hazards. By sourcing printed circuit boards from a trusted provider like Board Assembly, you ensure that each PCB is meticulously inspected and tested, guaranteeing that it can withstand even the most challenging environments.

When working on any tech-driven project, it’s crucial to focus on the longevity and performance of your components. High-quality PCBs offer enhanced reliability, reducing the likelihood of malfunction or failure in the field. This is especially important in industries where downtime can result in costly delays or safety hazards. By sourcing printed circuit boards from a trusted provider like Board Assembly, you ensure that each PCB is meticulously inspected and tested, guaranteeing that it can withstand even the most challenging environments.

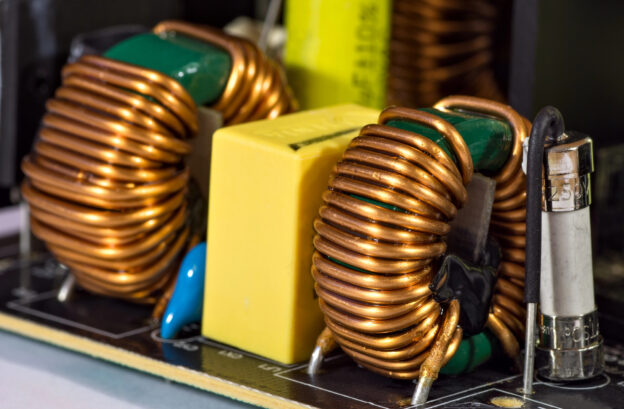

Another critical advantage of using high-quality PCBs is their ability to handle complex circuitry while maintaining efficiency. Whether your project involves compact devices or large-scale applications, well-designed printed circuit boards allow for optimal layout, minimizing noise and interference while maximizing performance. Quality control throughout the production process ensures that each board is built to precise specifications, eliminating errors and inconsistencies that could otherwise impact functionality.

Beyond functionality, investing in high-quality PCBs also enhances the overall reputation of your product. By delivering a reliable, robust solution to your customers, you establish trust and credibility, setting your business apart from competitors who may cut corners by using inferior components. The importance of partnering with a company like Board Assembly that prioritizes quality control cannot be overstated.

In conclusion, using high-quality PCBs in your projects isn’t just a technical requirement—it’s a strategic move to ensure long-term success and market differentiation. If you’re looking to integrate printed circuit boards that are built to last, perform reliably, and meet the highest standards, visit Board Assembly today to explore how their expertise and commitment to excellence can elevate your next project.

For example, ethernet cable assemblies are designed to provide service supporting bandwidth speeds up to 10 Gigabit Ethernet, such as large data centers, military field units, and medical facilities. For those applications that require a lightweight, smaller assembly that can transmit clearly and rapidly over great distances, support greater bandwidths, with high voltage isolation, then fiber optic cable assemblies would meet those needs. A few of the industries that utilize fiber optic cable assemblies, include aerospace, automotive, industrial, medical, and military applications.

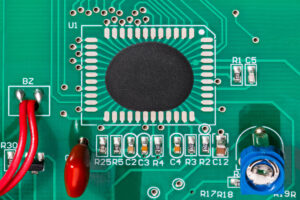

For example, ethernet cable assemblies are designed to provide service supporting bandwidth speeds up to 10 Gigabit Ethernet, such as large data centers, military field units, and medical facilities. For those applications that require a lightweight, smaller assembly that can transmit clearly and rapidly over great distances, support greater bandwidths, with high voltage isolation, then fiber optic cable assemblies would meet those needs. A few of the industries that utilize fiber optic cable assemblies, include aerospace, automotive, industrial, medical, and military applications. Every industry has its established lingo, which helps its members communicate more efficiently. If you are on the outside looking in, however, it can seem like they are speaking a foreign tongue. This becomes a problem when you need to work with vendors on ordering printed circuit boards for your device or your prototype. If you’ve gotten lost while trying to speak to your vendor (SMP, SME, SMD?), then you’ve come to the right place. Here is our no-nonsense guide on the most common terms in the printed circuit board industry:

Every industry has its established lingo, which helps its members communicate more efficiently. If you are on the outside looking in, however, it can seem like they are speaking a foreign tongue. This becomes a problem when you need to work with vendors on ordering printed circuit boards for your device or your prototype. If you’ve gotten lost while trying to speak to your vendor (SMP, SME, SMD?), then you’ve come to the right place. Here is our no-nonsense guide on the most common terms in the printed circuit board industry:

What Is a Contract Electronic Manufacturing Service Provider?

What Is a Contract Electronic Manufacturing Service Provider? Partner with a Trusted PCB Assembly Provider

Partner with a Trusted PCB Assembly Provider

The environmental impact of PCB production is significant due to the use of raw materials, energy-intensive processes, and potential chemical waste. Without sustainable practices, PCB manufacturing contributes to resource depletion and environmental degradation. As businesses and consumers alike prioritize eco-friendly solutions, adopting sustainable methods is no longer optional but essential for the industry.

The environmental impact of PCB production is significant due to the use of raw materials, energy-intensive processes, and potential chemical waste. Without sustainable practices, PCB manufacturing contributes to resource depletion and environmental degradation. As businesses and consumers alike prioritize eco-friendly solutions, adopting sustainable methods is no longer optional but essential for the industry.